We know people have been waiting for us to bring you a leatherman ratchet driver with the build quality and functionality you expect from 711L EDC tools, because we listen to customer feedback and read what’s being discussed online about ratchet bit drivers. We listen, we design, we build… and now we’re releasing the new 2025 711L EDC Inline Leatherman Ratchet Driver that we hope you’ll love as much as we do!

What are the key features of the 711L EDC Inline Leatherman Ratchet Driver?

Following our article on desirable qualities of leatherman ratchet drivers, here’s a TLDR overview of the innovative design of our new 2025 leatherman ratchet driver! We’ll expand on all of these points in more detail below.

- Bits won’t drop out or disappear into the socket

- Safe torque options to protect your leatherman tool

- Cross compatibility with your other EDC tools

- High quality build and finishing

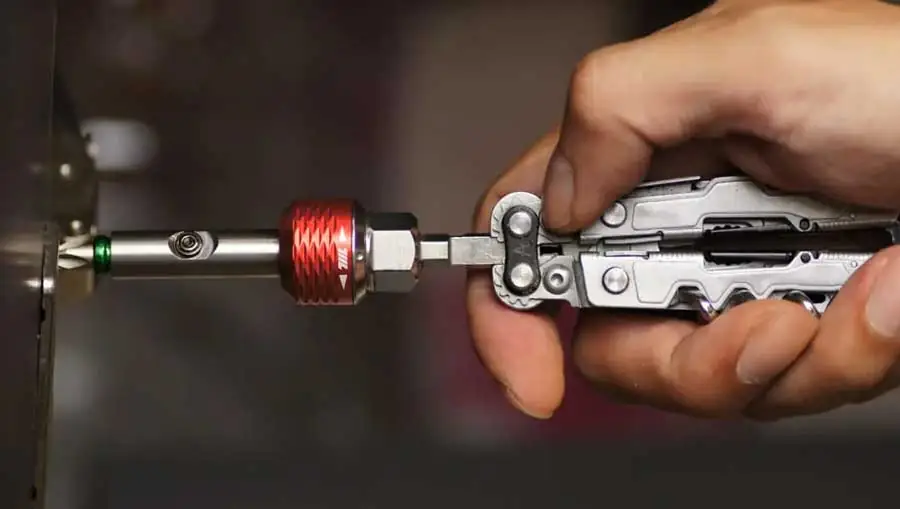

The new patented moving magnet stops short bits dropping out or disappearing into the driver body, and you can use it with a 14mm spanner or 711L Lollipop EDC bit driver when you’re at risk of exceeding the torque limits of your leatherman flat bit holder. Fully compatible with Klein and Vaco flip socket sets, and built to our usual extremely high standards with lifetime warranty option!

Rethinking the leatherman ratchet driver bit holder

The standard leatherman ratchet driver has a deep bit holder to accept long flat bits, with a magnet at the bottom to hold them in place. The problem is that because the socket is deep to hold flat drivers in place securely, the magnet is too far away from the end of standard length drivers to keep them in place.

EDC enthusiasts have remarked that when you pick up your leatherman ratchet driver with a short bit inserted into the holder to a usable depth, they tend to fall out. But if you insert the short bit all the way into the holder to contact the magnet, it is so deep inside that not enough of the bit is visible and available to use properly.

Movable magnet stops bits falling out of our leatherman ratchet driver

We thought about this problem and had a lightbulb moment – if a short bit can’t reach the magnet, we’ll bring the magnet to the bit! This was the origin of our patented movable magnet in the new 711L EDC inline leatherman ratchet driver.

You can pull up the magnet in the 711L EDC inline leatherman ratchet driver to release the bit easily (our patented sliding magnet functionality), and the magnet holds long and short EDC ratchet driver bits securely in place. This stops short driver bits dropping out onto your bench, falling in the long grass by your bike, or into the heart of that delicate bit of gear you are working on!

Taking care of torque with the 711L leatherman ratchet driver

A classic problem with leatherman ratchet drivers is that the leatherman tool flat bit socket cannot cope with high torque loads, tending to bend and twist open when overloaded. The torque limit for the EDC flat bit socket on a leatherman and on most EDC multitools is quite small, 20Nm of torque is plenty. So how do we increase the torque available without damaging our leatherman tool?

As usual, we spent a lot of time thinking around this and researching EDC user feedback and discussions about EDC tool compatibility and functionality, and your feedback on our new inline ratchet driver is telling us we made the right design choices, while creating several solutions for different uses of your leatherman ratchet driver!

Firstly, we added a 14mm hex section into our EDC inline leatherman ratchet driver. This means that you can switch to a ring spanner if you need to apply more torque. The 14mm hex is rated for 30Nm torque, and 20Nm for the flat section. Adding the functionality to use a spanner for additional leverage was a logical solution, and got us thinking about how to maximize compatibility with other EDC tools.

Cross compatible functionality of the 711L EDC inline leatherman ratchet driver

We’re all for reducing the number of tools you have to carry in your EDC toolkit, but without compromising on quality and functionality. So making our tools fit together to expand your EDC tool horizons is one of our design goals whenever we are building a new EDC tool… like our new 2025 leatherman ratchet driver.

Fitting the 711L Lollipop EDC Bit Driver to the inline leatherman ratchet driver

Our 711L Lollipop EDC Bit Driver is enormously popular, so it would be crazy not to be able to use it with our leatherman ratchet driver. That’s why we built in a short hex extension section to the flat bit, which gives a secure fit with the 711L Lollipop and with our Y-driver as well.

Getting a secure locking fit with Klein & Vaco flip sockets

Of course, there’s even more functionality with 711L EDC designs! The hex extension on the shank of our inline leatherman ratchet driver is exactly the right size and length to give a secure locking fit with both the Klein Tools Ratcheting 7-in-1 Impact Flip Socket Set / Nut Driver and Vaco Metric Impact Flip Socket Set. We know how popular flip sockets have become with the EDC community, so we wanted to add that extra compatibility for our customers.

Quality and build of the 711L EDC inline leatherman ratchet driver

We’ve used a high tooth count ratchet for ultra smooth operation, and drilled the shank so you can attach our inline ratchet driver to a key chain or wire tool loop. Our new 2025 leatherman ratchet driver has an attractive, durable aluminum ratchet housing with a diamond ground finish, paired with a rugged stainless tool steel shank and barrel. All manufactured to the considered, high quality standards you expect from 711L EDC!