If anyone needs reliable, lightweight, efficient tools then it’s going to be astronauts, so let’s look at how NASA astronauts use EDC in space. NASA astronauts have a history of using both standard and customized equipment on space missions, with the Omega Speedmaster series probably being the most famous example of EDC gear authorized for space use, but there are lots of routine jobs on the ISS and historic missions that just call for high quality tools that are lightweight and portable.

Can you use standard EDC gear in space?

This is astronaut Anne McClain working on the International Space Station in May 2025, photographed by her NASA crewmate Nichole Ayers. There’s no standard EDC gear in this photo, and that’s for two good reasons, one is that it’s not possible to handle small tools while wearing a spacesuit, and the other is that tools that are used in the extreme conditions outside the space station are specially designed to be able to reliably cope with extremely rapid temperature changes and the lubricant-stealing effects of the vacuum of space.

Specially designed tools for NASA space missions

For mission-critical jobs outside NASA spacecraft and the ISS, the tools are specially designed and manufactured, sometimes with specific custom tools for very specific tasks, like the ratchet designed and built for repair work on the Hubble Space Telescope in 1997 and seen in the picture above. These specialist tools are made for use by an astronaut working in vacuum with the restrictions on movement that come from working in a spacesuit.

Why is EDC gear used inside the International Space Station?

Do mission specialists and flight engineers use EDC gear when they go about their daily duties inside the ISS? We know that transferring mass into orbit is very expensive, even with the cost reductions achieved by modern reusable launch platforms, so the cost and benefits of everything going into space is weighed up very carefully, and literally! Inside the International Space Station you expect astronauts to be using EDC gear that you are familiar with using back on Earth.

What does it cost to get EDC gear into space?

A serious consideration with the use of any tools in space is the cost of getting the tool to its destination. It costs NASA $23,000 per kg to transport anything to the ISS, so they have to feel confident that what’s going up is worth taking at that price. The estimated cost of taking a Leatherman multitool to the ISS is approximately $6,000, so it’s not a decision taken lightly.

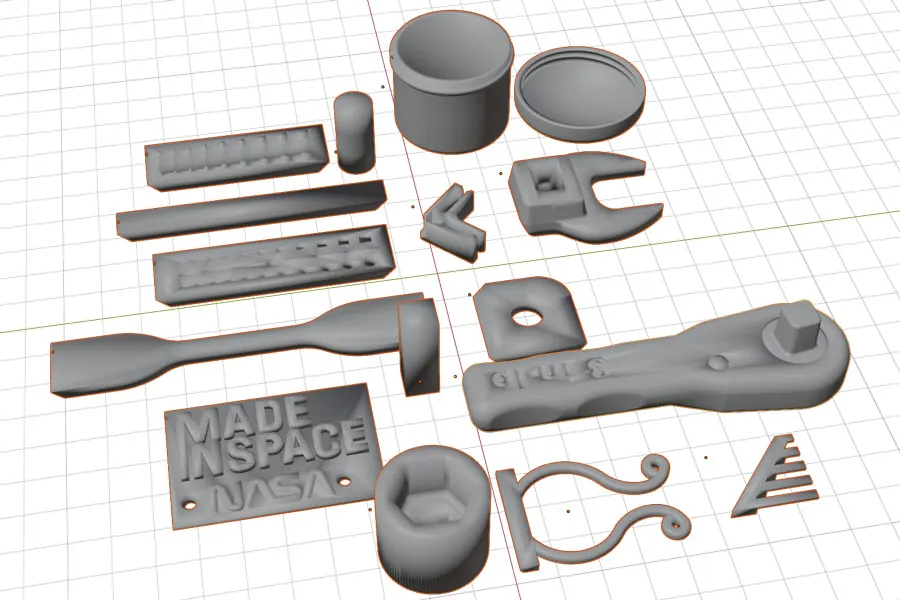

Can you 3D print your EDC gear on the ISS?

Experimental 3D printing of tools on the ISS is one possible solution, as NASA have recently demonstrated, although at present this is probably only really sensible for addressing gaps in the toolkits and EDC gear that they have onboard.

Do astronauts use standard tools in the international space station?

Back in 2001, when the space shuttle was being used to service the ISS, perhaps weight was less important. The picture above shows Expedition Three mission commander Frank L. Culbertson, Jr. used a full size ratchet wrench to do maintenance work on Unity Node 1 in the early days of ISS assembly.

What are astronauts using in the NASA image archives as EDC gear in space?

The NASA image archives are very extensive, and publicly available, so it’s possible to look through them to see what tools astronauts have and are using as EDC gear in space. It’s a time consuming task, but fortunately there are EDC enthusiasts who have taken the time to try and discover what EDC gear is being taken into orbit.

711L EDC Gear: tough, precision tools you can take anywhere!

Standard multitools and accessories are a functional choice for contemporary astronauts. Cost constraints on space exploration today and significant budget reductions compared to the Apollo missions and space shuttle programme make it sensible for NASA to choose proven off-the-shelf EDC gear for work inside the ISS, even if they still need to make special tools for EVA tasks. Included in the current EDC gear on the ISS is a 711L flex-head ratchet wrench, and we’re going to talk about that some more in our next article!