Custom knives are made from a variety of materials that impact their performance, aesthetics, and durability. Here are the most commonly used materials for different parts of custom knives:

1. Blade Materials

The blade material affects sharpness, edge retention, corrosion resistance, and overall durability.

- Stainless Steel: Known for corrosion resistance and durability, stainless steels are popular for custom knives. Common types include:

- 440C: High corrosion resistance, good wear resistance, often used for EDC knives.

- 154CM/CPM-154: High-performance stainless steel with excellent edge retention and toughness.

- S30V/S35VN: Premium steels known for great edge retention, toughness, and corrosion resistance, commonly used in high-end knives.

- Carbon Steel: Preferred for its toughness and ease of sharpening, though it requires more maintenance to prevent rust.

- 1095: One of the most popular carbon steels, known for its durability and ease of sharpening.

- O1: Tool steel with excellent edge retention and toughness, but prone to rust without proper care.

- Damascus Steel: Known for its unique wavy patterns, it is a blend of different steels that creates both functional and visually striking knives. It can offer good toughness and edge retention, though performance can vary depending on the specific blend of metals used.

- High-Speed Steel (HSS): Often used for industrial applications, HSS (like M2 or M4) offers excellent wear resistance and edge retention, making it a good choice for custom knives intended for hard-use tasks.

- Tool Steels: Known for high hardness, strength, and toughness.

- D2: A semi-stainless tool steel, famous for its wear resistance, commonly used for custom knives requiring a tough edge.

2. Handle Materials

Knife handles come in a wide range of materials that provide different grips, looks, and durability.

- Wood: A classic and aesthetic choice, offering warmth and comfort in hand. Popular woods include:

- Cocobolo: Dense, oily hardwood with rich colors, often used in high-end custom knives.

- Ironwood: Extremely durable and dense, often used in premium knives.

- Maple Burl: Offers unique grain patterns and a luxurious feel.

- Micarta: A composite material made from layers of linen, canvas, or paper soaked in resin. It’s tough, lightweight, and offers a grippy texture, even when wet.

- G-10: Another composite material made from fiberglass layers, known for being lightweight, tough, and water-resistant. G-10 handles are often used in tactical knives.

- Carbon Fiber: Ultra-light, strong, and visually striking due to its woven pattern. It’s a premium material often found in custom and high-end knives.

- Titanium: Lightweight, durable, and resistant to corrosion, titanium is often used in premium knife handles, especially for frame locks.

- Bone/Stag Antler: Often used for traditional or collectible knives, these materials offer a rustic, natural look and a comfortable grip.

- Synthetic Rubber (Kraton): Provides a non-slip, cushioned grip, often used in knives designed for hard or wet use, like survival or tactical knives.

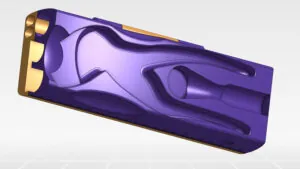

3. Bolsters and Liners

- Brass: A classic choice for bolsters and liners, brass adds weight and a traditional aesthetic to custom knives.

- Stainless Steel: Provides durability and a clean look, often used in modern custom knives.

- Titanium: Lightweight, strong, and corrosion-resistant, often used in high-end knives, especially for the liner or bolster.

- Copper: Adds a striking appearance and patinas over time, giving the knife a unique character.

4. Locking Mechanisms

Custom knives can feature a variety of locking mechanisms made from durable materials:

- Titanium and Stainless Steel: Used for frame and liner locks, these materials provide strength and reliability for locking mechanisms.

5. Sheath Materials

- Leather: Traditional, durable, and aesthetically pleasing, leather sheaths are often used for custom fixed-blade knives.

- Kydex: A modern thermoplastic material known for its durability and customizability. It offers excellent protection and retention for tactical knives.

These materials contribute to the performance, feel, and appearance of a custom knife, and the right combination depends on the intended use and personal preferences.