Leatherman ratchet drivers are an increasingly popular EDC multitool accessory, so we’re going to take a look at the design characteristics, features and engineering challenges that you might want to think about if you’re updating your EDC toolkit for 2025 with a Leatherman ratchet driver.

What is an inline Leatherman ratchet driver?

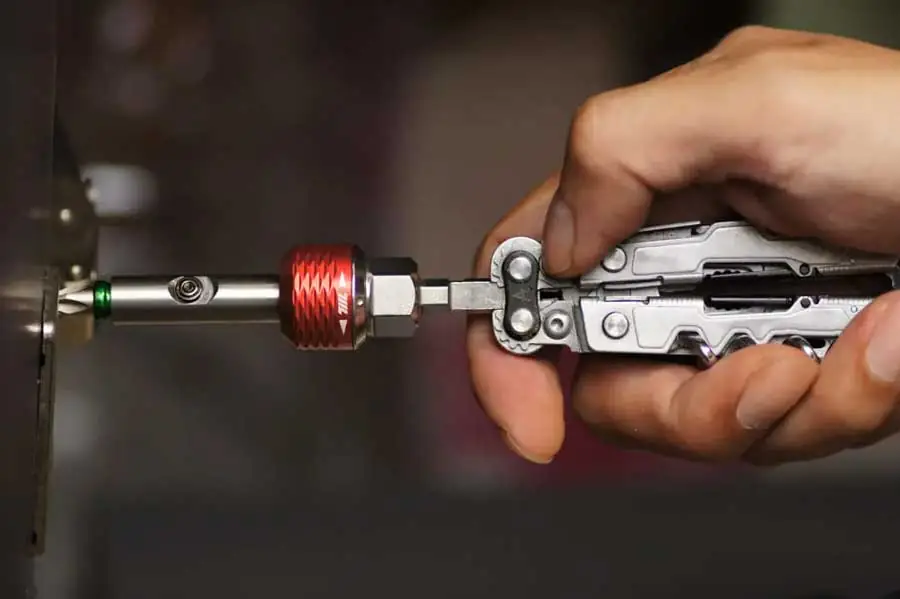

In case you’re not familiar with this specific type of EDC tool, the inline Leatherman ratchet driver is a bit driver with ratcheting action that is designed to fit in the flat bit holder of many popular Leatherman multitools. Unlike standard right-angle EDC ratchet wrenches, the ratcheting action is ‘in line’ with the bit holder, but you can rotate the bit holder to a right angle with the multitool to get added leverage.

This type of tool is commonly known to EDC users as a Leatherman ratchet driver, even if it’s not made by Leatherman Tools, and this class of EDC tools includes compatible flat bit holders for other EDC multitools from different manufacturers and brands. You can use a flat bit inline ratchet driver with any compatible bit holder, grip, or tool that can accept flat as well as hex shanks.

How do you use an inline Leatherman ratchet driver?

This may sound like a simple question, but it hides several design and use challenges for Leatherman inline ratchet drivers that you may not have considered. Perhaps the most significant problem is the torque limitations of the bit holder on Leatherman or other multitools.

Skeleton-style flat bit holders are notoriously fragile when subjected to twisting moments, so you have to take care not to over torque your EDC multitool with a bit mounted in a flat bit holder. The danger zone for torque on this component is surprisingly low – 20Nm is a typical working limit before you risk bending and distorting the bit holder.

What are people saying about inline Leatherman ratchet drivers?

One of the most common issues is that Leatherman Tool branded ratchet drivers are hard to get hold of. They seem to be made in small batches that sell out rapidly, and this has created an aftermarket for Leatherman ratchet drivers with inflated prices – up to 10x the retail price.

This encourages other people to manufacture Leatherman compatible ratchet drivers and has resulted in a lot of different options on the market, some of which turn out to be of poor quality, but functionality is similar to the standard Leatherman ratchet driver. Quality differences between different EDC ratchet wrenches and drivers is an important consideration, so it is a good idea to do some research.

Obviously, we would recommend our 711L inline Leatherman ratchet driver, but we don’t want you to just take our word for it being one of the best ones on the market. We encourage all EDC fans to participate in the EDC community, join the discussions online to find out what meets their needs, and get honest feedback from other EDC users.

What are the design issues with Leatherman ratchet drivers?

We’ve mentioned how easy it is to over-torque the flat bit holder on your Leatherman or other multi-tool. People are tempted to turn the holder sideways to use the multitool as a lever for twisting the bit. This is very likely to end in tears as the bit holder is simply not designed to take that sort of punishment. If you want to get more torque, you need to be able to fit the ratchet driver to a more robust grip.

Do all your EDC bits fit your Leatherman ratchet driver?

Many proprietary multi-tool flat bits are much longer than standard short hex bits, so remember that the point of having an inline Leatherman ratchet driver is to be able to attach it between your Leatherman tool and your existing EDC multitool flat bit collection. It should hold the bits securely so they don’t drop out, which is something we’ve all experienced, and the bit always goes somewhere you don’t want it to be!

Ratchets should be robust and have a high tooth count

All ratchet drivers need a high tooth count for smooth operation (like the 711L EDC ratchet wrenches in the photo above), and especially for awkward spaces. Coarse ratchets are useless if you can’t turn them far enough to get to the next click.

Also, remember that low-quality ratchets with high tooth counts are fragile and tend to fail. Ideally, you want a well-engineered and robust ratchet with a high tooth count for optimum performance that doesn’t compromise on the quality of materials used to make it.

How compatible is the Leatherman ratchet driver with the rest of your EDC toolkit?

If you’re going to be spending money on a Leatherman ratchet driver, how well does it integrate into the rest of your EDC toolkit? Can you fit it to your Y-Driver (or Lollipop)? Can you use it with popular bits and sockets, or will you be restricted to only using specific long, short, flat, or hex bits? Can you fit the ratchet to other tools and grips, or will it only fit your multitool?

Take your time, read the reviews… and check out the new 711L inline Leatherman ratchet driver!

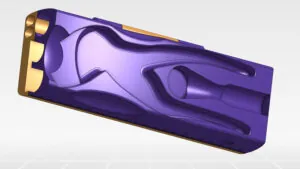

Of course, the new 2025 711L inline Leatherman ratchet driver is going to be the one to beat – we took care over the design to make sure that it has the strength, reliability, smooth operation, and wide compatibility to be a frequent-use go-to tool for any EDC toolkit, and you don’t even need a Leatherman tool to use it! In our next article, we’ll be explaining why we’re so proud of this new addition to our EDC tools for Leatherman!