Inline EDC ratchet drivers can add another level of efficiency and convenience to the bit drivers and socket adapters in your EDC gear. Let’s have a look at the important features of inline EDC ratchet drivers and see what features you might look for when you are thinking about adding one to your EDC toolkit.

What is an inline EDC ratchet driver?

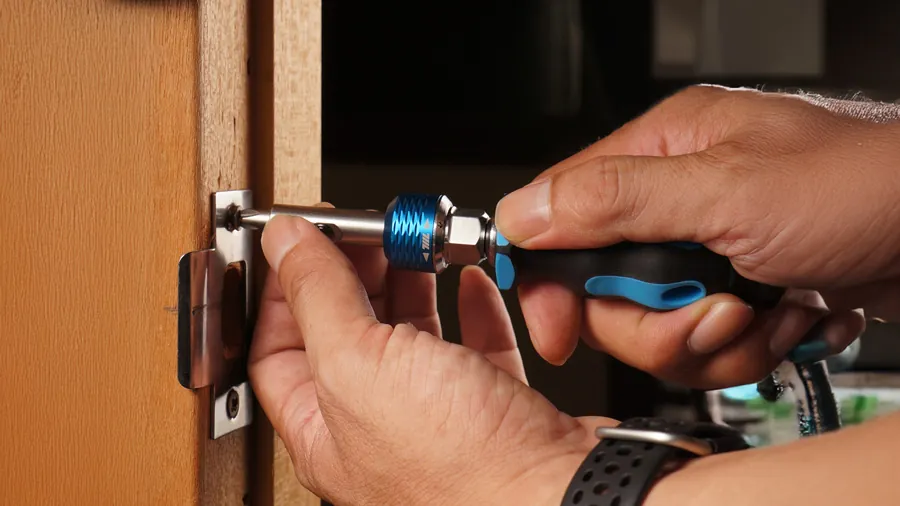

We’re all familiar with right-angle EDC ratchet wrenches, which apply leverage to sockets and bits inserted in the centre of the ratchet wheel. Inline EDC ratchet drivers have the same unidirectional ratcheting convenience, but attach in line to a bit driver. You can insert them in a screwdriver style grip, like a Klein tool, or use a hybrid like the classic 711L Lollipop EDC Bit Driver. The Lollipop gives you the option of inline or angular torque from the same tool.

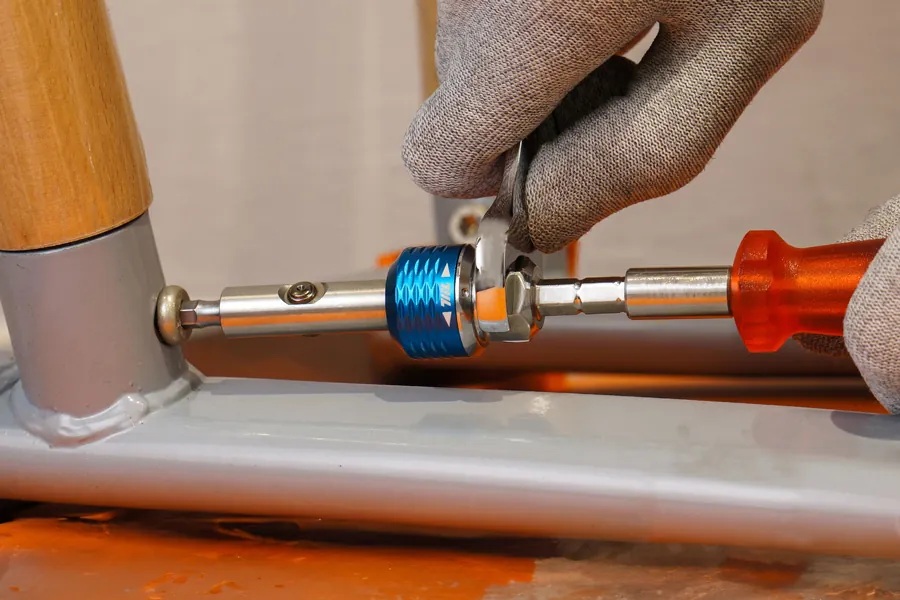

How do you get more torque from an inline EDC ratchet driver?

Inline EDC ratchet drivers rely on the torque available from the bit driver they are attached to. In the case of flat shank EDC ratchet drivers for Leatherman, you can increase torque by opening out your multitool or Leatherman, but be aware that it’s easy to over-torque the flat bit holders in multitools and twist them open by doing this! 20Nm is a typical working limit for a multitool flat bit holder.

Some flat bit adapters and inline tools only fit the flat bit holders in multitools, and are not compatible with other hex bit holders, which can limit their usefulness. A full size ¼” hex shank is tougher than a flat shank, which can be bent or broken as well as potentially breaking your expensive Leatherman multitool flat bit holder if you get carried away! Keep this in mind or look for an inline ratchet driver with a safe torque option.

Tips for EDC ratchet driver torque management

If you are intending to use an inline EDC ratchet driver for heavy duty work it’s best not to rely on fitting it to a flat bit holder in a Leatherman tool or equivalent, but use a high torque ¼” hex bit driver, like the 711L Lollipop EDC Bit Driver or our EDC Y Driver, as the base tool of your inline EDC ratchet driver kit.

We often select inline ratchet drivers to get into tight spaces that aren’t accessible with a wrench, but an inline ratchet driver that includes a machined hex (like the 711L version) that can be torqued with a standard small wrench offers a safe alternative to using a less robust tool or socket combination. Alternatively, consider using an EDC ratchet wrench to get extra torque.

Can you use any type of bits in an inline EDC ratchet driver?

This depends on the design of the inline EDC ratchet driver. A common problem for the EDC community is having a combination of double-ended, short, and long bits among their favourite and most used EDC gear. We all have had the unpleasant experience of feeling and hearing a bit drop out of a bit holder and disappear into the depths of our current project, with results varying from the comical to total disasters.

What EDC bit compatibility do you need for your inline EDC ratchet driver?

- Short EDC hex bits

- Long EDC hex bits

- Double ended EDC hex bits

- Flat EDC bits for Leatherman / multitools

Look for an inline EDC ratchet driver that is genuinely compatible with a wide range of bit types and offers a secure mechanism or magnetic lock that you can depend upon to keep your bits where they’re supposed to be; in your ratchet driver, and not jammed in the depths of your PC, hidden in the long grass by your bike, or wedged under a PCB in your drone or RC car!

What are the most important features of inline EDC ratchet drivers?

The most important features of inline EDC ratchet drivers are robust torque capabilities, which requires high quality construction when making any EDC gear, a high tooth count precision ratchet, and multi-bit compatibility. These are all design and engineering considerations that can make a lot of difference to the quality of your experience of any inline EDC ratchet driver.

- Torque capability & robust construction

- Precise ratcheting with high tooth counts

- Secure bit retention for all types of EDC bit

Can you increase the torque if you need it?

Look for an inline EDC ratchet driver that you can fit to a wrench or high torque capable grip, like the 711L EDC Lollipop Bit Driver. The correct combination of ratchet driver and grip will make your jobs much easier. Inline ratchets are most commonly used to ensure screw retention in precision work, but having to switch to another driver to do the final turn because you can’t get enough torque is not very efficient.

How precise is the ratcheting action?

Ratchet precision comes from high tooth counts and accurate engineering. Loose, sloppy ratchets have to be rotated further to go between clicks (which is a limiting factor for many EDC ratchet wrenches), you need a positive, tight ratchet to maintain a secure grip on the screw, nut or bolt you are working on.

How are bits held securely in the ratchet driver?

Most EDC bit drivers use magnets to hold bits in position, some use sleeves and locking mechanisms with spring loaded bearings or clips. Magnets are a simple solution, except when you have EDC bits of different lengths. A deep socket with a magnet at the base will swallow up short EDC bits and most double-ended bits, but a short socket won’t fit your longer bits securely.

Check out our 711L EDC Inline Ratchet Drivers

We’ve covered a lot of ground here discussing the features and requirements of EDC inline ratchet drivers, and that’s because we’re engineers, and it’s how we approach the design, prototyping, testing and manufacture of all our 711L EDC gear.

In our 711L EDC designs we’ve paid close attention to manufacturing inline ratchet drivers that tick all the boxes, and are built with the high quality materials and attention to detail that our customers expect. Check out our 2025 EDC inline ratchet drivers on Amazon in hex and flat shank versions, and get more information about our flat shank Leatherman inline ratchet driver on our website and blog!